IAG 800 FA20 DIT Closed Deck Case Half Set for 2015-21 Subaru WRX

Have questions?

-

Guaranteed Quality

Best Parts Every Time

-

Expert Help

Build Advisors Are Standing By

-

Secure Shopping

SSL Verified

-

Worldwide Delivery

Free shipping on most orders over $249 in US 48

IAG Performance

IAG 800 FA20 DIT Closed Deck Case Half Set for 2015-21 Subaru WRX

- SKU:

- IAG-ENG-C800-OPT

- Availability:

- Built in the Order Received

- Proposition 65:

P65 WARNING: Cancer and Reproductive Harm www.P65Warnings.ca.gov.

P65 WARNING: Cancer and Reproductive Harm www.P65Warnings.ca.gov.

IAG 800 FA20 DIT Closed Deck Case Half Set for 2015-21 Subaru WRX

IAG 800 FA20DIT CLOSED DECK CASE FOR 2015-2021 SUBARU WRX

PLANNING TO BUILD YOUR OWN ENGINE? START HERE

It's no secret that the OEM Subaru case halves, or "block," aren't exactly the strongest. IAG has developed a process to greatly improve the strength of the OEM Subaru FA20 Case Halves to combat the effects of high cylinder pressures brought on by increased power and boost. Our proprietary "Closed Deck" System works by supporting the top of the cylinder in the weakest areas and prevents movement and expansion which can lead to cracks and failures. Despite the additional material supporting the cylinder walls, there is no concerns with overheating or coolant flow because the area around the middle of the cylinder still maintains the same coolant area. The custom IAG closed deck inserts are machined with holes for oil and coolant to pass through the same as stock. Each IAG 800 FA20 DIT WRX Case includes machining for 1/2" head studs and a cylinder gasket "o-ring" groove to aid in head gasket sealing. If you're one of those people who prefer to do your own builds we now offer our legendary closed deck case halves for purchase separately. Simply install your crank, rods, and pistons to your own specifications and be confident that the case halves will take the power and prevent common cylinder wall failures.

THE IAG CLOSED DECK PROCESS

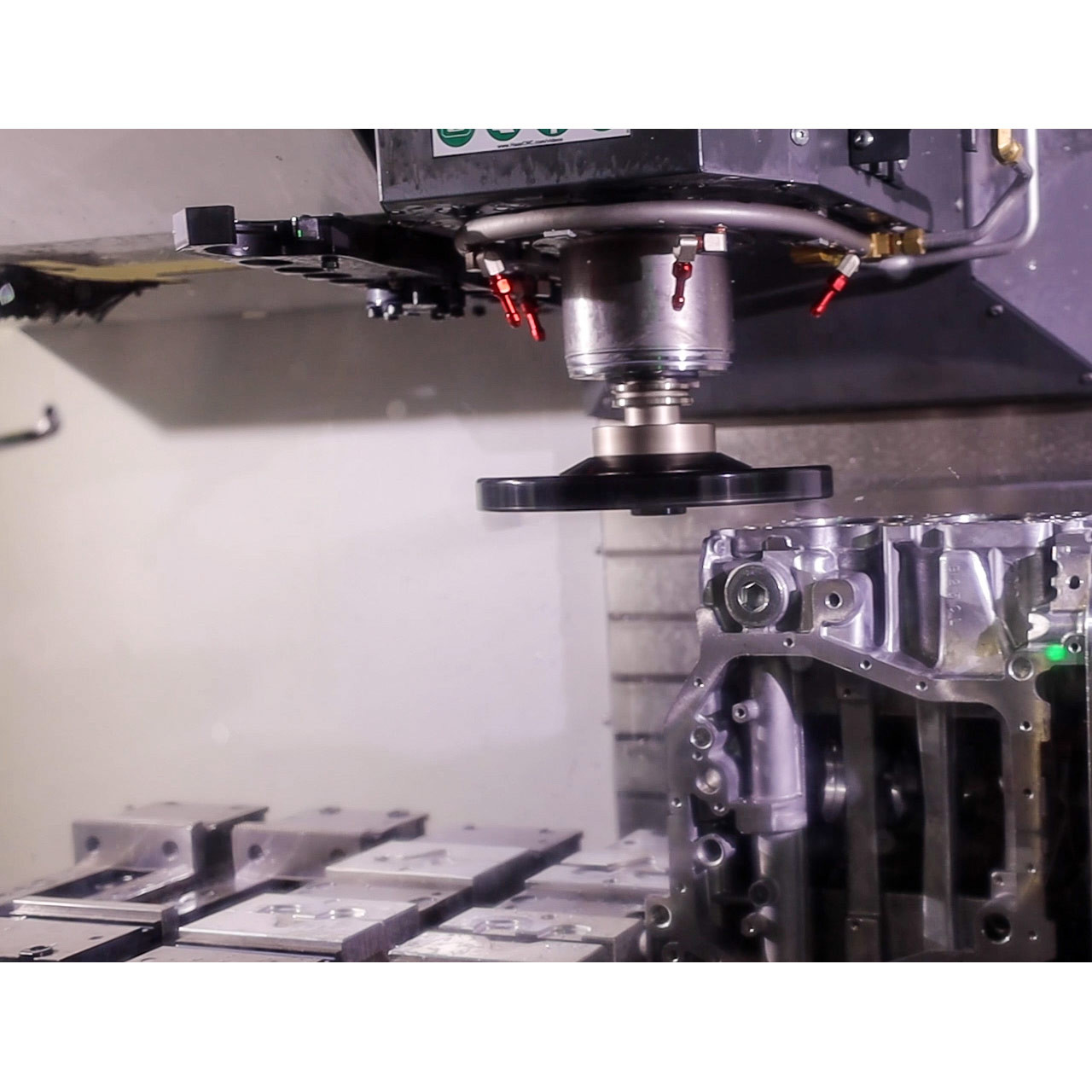

The IAG Closed Deck conversion is performed 100% in-house by our engineers and experts using state-of-the-art equipment. The IAG Closed Deck starts with a new OEM FA20 bare case. The case is loaded and fixtured to a 4th axis rotary indexer in our Haas VF4-SS CNC Vertical Machining Center. It is supported by the main journals using a precision ground 2-inch bar and tailstock which ensures the datum is the main journals. This method gives us a true reference point to perform all machining operations. A Rennishaw probe is utilized to check that the case is fixtured true, and once confirmed the machining process begins.

Once the case is fixtured, the first step is to mill out pockets for CNC inserts. Rather than attempting to install inserts into an inconsistent cast case, the pockets are milled out to exact dimensions creating a consistent area that accepts our precision inserts. Once the pockets are machined, the case is removed from the mill and placed into a block oven at a low temperature. Our pre-machined closed-deck inserts are simultaneously chilled using dry ice. When the case and inserts have reached our desired temperature, they are moved into our install station, which holds the block and lightly presses the inserts into position on one side of the deck surface. This process is repeated on the other side and then the partially completed case is moved to a cooling rack. In the next step of our process, the case is loaded and fixtured back into the VF-4SS after reaching room temperature. During this stage, the flanges left from machining the inserts are milled close to the case deck surface. Features such as coolant passages and case bolt access positions are machined. Finally, each deck surface is machined true and flat using a Poly Crystal Diamond insert.

SPECIALLY DESIGNED INSERTS

Our machining process converts the FA20's open deck to a complete closed deck and features the use of cast insert material that closely matches the metallurgy of the aluminum case material in a factory Subaru FA engine block. By using a similar cast material (rather than billet), we ensure that during expansion and contraction the materials grow and shrink at similar rates, which is vital for maintaining roundness within the top of the bore. The inserts are machined from ¾" cast material. Once the deck is surfaced, the result is a true ½ inch finished insert thickness.

O-RING GROOVE & 1/2" HEAD STUDS FOR HEAD GASKET RELIABILITY

Each IAG 800 Closed Deck FA20 DIT WRX Case includes extra machining to ensure reliability of the cylinder head gaskets. During the maching processeach case gets drilled and tapped to accept 1/2" Head Studs (Sold Separately.) Along with the upgraded head studs, a receiver groove is machined into the surface of the deck to accept an "o-ring" wire. When installed, the "o-ring" stands slightly above the deck and provides extra tension on the head gasket to seal combustion.

FINAL BORE AND HONE

Every IAG Closed Deck case must be bored and honed after the closed deck process. During the closed deck process the cylinder walls become slightly distorted and an overbore must be performed to the correct this distortion and prepare the block to accept new pistons. FA20 Case Halves must use 86.1mm pistons. IAG offers the Bore and Hone service with each of our closed deck case halves. When selected, the case half set is fitted with custom deck plates and bored and honed in our state-of-the-art Sunnen SV-30 Computer Controlled Cylinder Hone. YOU MUST PURCHASE OR SEND IN YOUR PISTONS FOR MEASUREMENT AND SIZING IF YOU SELECT THE BORE AND HONE OPTION.

What's Inside:

IAG 800 FA20 DIT WRX Closed Deck Case Includes:

-

(x1) IAG 800 Closed Deck Converted Case Halves (Using brand new FA20 DIT Case / Stock Bore 86mm) *86.1mm Bore and hone additional and required before final assembly! -

(x1) Machined for 1/2" Head Studs

- (X1) Machined for Head Gasket "O-ring"

Power Rating:

Power: The IAG 800 Closed Deck Case has a power output rating of 800 BHP

Installation Instructions:

Please Note: Overbore must be performed (86.1mm is the preferred bore) before assembly!

*Attention: Special note about using ARP Case Bolts - IAG recommends line honing the case when using ARP Case Bolts to remove any distortion created by the hardware. IAG installs ARP CASE BOLTS with 30W engine oil using OEM SUBARU torque specs and procedures. Other torque specs and lubricants may lead to case distortion damage.

Please review the PDF document below regarding installation, break-in procedures and warranty information. ![]() PDF After Sale Document - Contains Shipping, Engine Care and Warranty Information

PDF After Sale Document - Contains Shipping, Engine Care and Warranty Information

SHIPPING

FREE SHIPPING on orders of $250 or more* Simply look for the logo to enjoy free shipping on selected items throughout the store. Oversized packages and freight shipments do not qualify for free shipping. If the items in your order which qualify for 'Free Shipping' total $250 or more, your order ships FREE! Free shipping is only available to the continental United States also referred to as the “lower 48 states”.Shipping Policy: All products sold on the shopping cart are shipped by UPS or USPS. All packages include shipping insurance in case they are lost or damaged. USPS requires signature confirmation on all insured orders over $200.00. USPS shipping times are estimated and not guaranteed. UPS tracking numbers are automatically generated when a package ships and the number is sent to the email address you provided. If a package contents is damaged during shipping please notify the shipping driver and file a claim with the shipper. You have 14 days to inspect your shipment and contents. After that period of time, IAG is no longer responsible for missing items. You have 30 days to report any damaged or incorrect items, after that period of time IAG is no longer responsible for returns or exchanges. You can contact us by Email or call 410-840-3555 for assistance. *International orders are subject to customs charges, duties or fees. Please check with your local customs office before ordering. IAG is not responsible for international customs charges, duties or brokerage fees.

Drop Shipping: Some items require drop shipping to complete an order. These products are shipped from manufacturer or distributor warehouses across the country. In some cases, this may speed up delivery time. In other cases, it could add 1-3 days to the delivery time. If you have a question regarding an order please contact our sales desk at 410-840-3555.

Order Processing: Orders placed after 3PM EST may not be processed the same day. Order processing may take 24-48 hours. USPS orders placed after 10am EST will ship the following business day if the items are in stock

RETURNS

How do I return an item?

You have 14 days to inspect your shipment and contents. After that period, IAG is no longer responsible for missing items. You have 30 days to report any damaged or incorrect items, after that period IAG is no longer responsible for returns or exchanges. All stocking products are subject to a 30 Day return policy. The item(s), when approved for return, are subject to a 20 percent restocking fee. Canceled orders may be subject to a 20 percent cancellation fee. All product returns require a return authorization number before being shipped back to IAG or the manufacturer. An “RMA” number is obtained by calling the IAG Support Desk at 410-840-3555 or emailing support@iagperformance.com. Some products may require shipping back to the manufacturer for inspection before a return or exchange may be processed. Some products may not be able to be returned. Products that have been modified or installed are not eligible for return. There are no returns or cancellations for Special Order/Made to Order items and Electrical Components (including the COBB Accessport). Items returned after the 30 Day return period without an RMA will be refused. Canceled service appointments with deposits are non-refundable.

Refunds take 30 days or less. Payments made by Credit Card or PayPal are returned back to the original account used during the transaction. There are no cash returns; we will issue a business check for the return of funds. Refunds are decided by the management and not by sales staff. Canceled service appointments with deposits are non-refundable.

IAG Performance Product Warranty (Excluding - Short Blocks / Long Blocks)

This limited warranty gives you specific legal rights and you may also have other rights, which vary from state to state. We limit the duration and remedies of all implied warranties, including, without limitation, the warranties of merchantability and fitness for a particular purpose to the duration of this express limited warranty. Some states do not allow limitations on how long an implied warranty lasts. The remedies described below are your sole and exclusive remedies and our entire liability for any breach of this limited warranty. Our liability shall under no circumstances exceed the actual amount paid by you for the product, nor shall we under any circumstances be liable for any consequential, incidental, special or punitive damages or losses, whether direct or indirect.

This warranty covers defects in materials and workmanship of your IAG Performance Product for 12 Months or 12,000 Miles from the date of receipt.

IAG will repair any IAG Manufactured Product that proves to be defective in materials or workmanship within the warranty period. If a repair is not possible, we will either replace your Product with a new Product of similar composition and price, or refund the full purchase price of your Product, at our sole discretion. There is no charge for inspection but the buyer is responsible for shipping charges.

IAG Performance Engine Warranty

For more information concerning our engine warranty please visit IAG Performance Engine Warranty Page

Other Manufacturer Products:

Products not manufactured by IAG are subject to the individual manufacturer warranties which may apply. If you have questions concerning the fitment, appearance, or performance of your item, please contact a member of our customer support team for assistance.

Our customer service team is happy to assist you with the products purchased from IAG Performance. Our support associates can help you with installation support, troubleshooting advice, and help to identify possible manufacturer defects.

For products that are found to have defects, our support department can provide the contact information for the manufacturer to arrange a warranty inspection and, if applicable, any necessary repairs or replacement shipments.

You may also contact the manufacturer directly for information regarding product eligibility and specific terms and conditions of warranty coverage.