IAG Performance / Crest CNC Stage X 2.5L Subaru Billet Aluminum Short Block For WRX, STI, LGT, FXT

Have questions?

-

Guaranteed Quality

Best Parts Every Time

-

Expert Help

Build Advisors Are Standing By

-

Secure Shopping

SSL Verified

-

Worldwide Delivery

Free shipping on most orders over $249 in US 48

IAG Performance

IAG Performance / Crest CNC Stage X 2.5L Subaru Billet Aluminum Short Block For WRX, STI, LGT, FXT

- SKU:

- IAG-ENG-SX25

- UPC:

- 887753904157

- Availability:

- Usually Ships in 24 to 72 Hours

- Proposition 65:

P65 WARNING: Cancer and Reproductive Harm www.P65Warnings.ca.gov.

P65 WARNING: Cancer and Reproductive Harm www.P65Warnings.ca.gov.

IAG Performance / Crest CNC Stage X 2.5L Subaru Billet Aluminum Short Block For WRX, STI, LGT, FXT

IAG PERFORMANCE / CREST CNC 2.5L SUBARU BILLET ALUMINUM SHORT BLOCK 1150+ BHP

THE IAG PERFORMANCE / CREST CNC STAGE X SHORT BLOCK

The IAG Performance / Crest CNC 2.5L Subaru Billet Aluminum Short Block aspires to revolutionize the Subaru performance tuning market by reinventing the EJ and addressing virtually every weakness that exists in max-power builds. The Stage X Billet Short Block is engineered to eliminate case flex in high-power EJ builds, making it possible to reliably run at a power output rating of 1150+BHP. This short block is equipped with radiused coolant and oil galleries to improve flow, a 4-bolt bottom end for added strength, and replaceable iron sleeves, making rebuilds easier. If you are looking for an EJ engine that can deliver high horsepower without any compromises, then the Crest CNC/IAG Stage X billet short block is the perfect choice!

SOLID FOUNDATION BY CREST, POWERED BY IAG

The Stage X Billet Short Block is a complete short block built by IAG on the Crest billet platform. Crest CNC (formerly Willall), is renowned for their precision-machined billet aluminum engine blocks and components. With Crest’s proven track record of producing blocks that endure the rigors of high-output engines, combined with our expertise in high-powered aftermarket Subaru builds, this collaboration delivers an unbeatable foundation for those pushing the limits of performance.

SOLID BILLET ALUMINUM PLATFORM WITH 100% NEW COMPONENTS

The Stage X Billet Short Block case is precision machined by Crest CNC using 6061-T6 Aerospace Aluminum and reinforced with Darton Ductile Iron Sleeves. The billet case halves are meticulously hand-assembled by our expert Subaru technicians, and include the IAG Spec Billet crankshaft, custom IAG-Spec +2mm Tri-Beam connecting rods and ARP 625+ rod bolts, along with IAG Spec JE 99.5mm FSR 2618 forged pistons. The Stage X Short Block also includes ACL or King rod and main bearings and is balanced and blueprinted. Finally, the case halves are sealed with new ARP main/case bolts and sealant.

NEXT-LEVEL INNOVATION

The IAG Performance / Crest CNC 2.5L Subaru Billet Aluminum Short Block is engineered with numerous advanced features that enhance strength and reliability. Precision machined from solid aluminum billet and hard anodized to prevent marking or staining, this short block is multiple times stiffer and stronger than the stock case, making it ideal for high-powered builds. Additionally, increased material thickness has been strategically added in all known weak points, particularly around the head studs and bottom end location, enhancing the block's resilience.

Additional innovations featured in the Stage X Short Block include a unique 4-bolt bottom end design that provides extra strength and stability. The block’s bolt threads are rolled, rather than conventionally cut, ensuring a solid grip on hardware. Not only does this short block maintain full cooling system operations, but it incorporates the use of its radiused coolant and oil galleries for improved flow and less foaming and/or turbulence. Finally, the Stage X Short Block is compatible with all factory engine bay ancillaries (i.e., AC/PS/etc.).

IAG’S FIRE-LOCK SYSTEM: NO MORE HEAD GASKET WORRIES

The IAG Performance / Crest CNC 2.5L Subaru Billet Aluminum Short Block features our proprietary "Fire-Lock" receiver groove machining and is compatible with our IAG "Fire-Lock" Head Gaskets. This system has been proven in our record setting race cars to be the strongest Subaru head gasket system ever produced. To achieve these results, our engineers separated the combustion chamber sealing from the fluid sealing aspects of the head gaskets. Our machinists carefully machine a lip at the top of each cylinder to accept the "Fire-Lock" ring. With the ring locked in place, it stands firmly above the deck, providing a superior seal. The separate gasket bodies take care of sealing oil and coolant passages, while keeping them out of the combustion chamber. 14mm Head studs hold the assembly together. (IAG "Fire-Lock" Head Gaskets and Head Studs Sold Separately).

CUSTOM JE PISTONS

The IAG Stage X Short Block features JE 99.5mm FSR 2618 custom pistons, engineered to deliver outstanding performance for both street driving, as well as for drag and rally racing applications. These pistons feature thicker ringlands and are treated with electroless nickel-plating, resulting in a stronger piston that can stand up to highly boosted applications. Additionally, they come equipped with .250" / .927” H13 tool steel wrist pins, providing a significant upgrade over standard chromoly pins, ensuring enhanced reliability under extreme conditions.

BUILT TO PERFORM

A common failure point of the OEM Subaru short block are the piston ringlands. The metal ledges on the pistons that hold the compression rings in place can withstand regular usage but are prone to failure when used with modified components. Cracked or broken ringlands often lead to increased oil consumption and eventual bearing failure if the oil is not closely monitored. In contrast, the increased ringland thickness on the custom JE pistons used in the IAG Stage X Short Block are designed to match up to its high-powered capabilities, ensuring durability and reliability even under extreme-performance conditions.

FORGED ALUMINUM ALLOY

The OEM EJ25 pistons continue to be produced using a hypereutectic cast design, which is susceptible to irregularities in both the casting process and the materials used, leading to potential weaknesses. These cast pistons simply lack the strength needed to handle the extreme power output of this high-performance short block. This is where our custom JE pistons come in; forged from a durable 2618 T6 Alloy with a unique silicone additive, these JE pistons effectively absorb the direct shock and impact of combustion. Engineered to withstand ringland damage due to detonation and preignition, they feature a higher strength material and have been custom designed to feature thicker ringlands.

PROFESSIONALLY ASSEMBLED AND READY TO INSTALL

Our team of certified Subaru specialists at IAG Performance takes great care in assembling each IAG Stage X Short Block. These specialists have now built over 14,000 Subaru engines and counting. Equipped with an advanced selection of tooling and state-of-the-art equipment, we guarantee the quality of all our engine blocks. Each block is meticulously crafted and thoroughly checked, ensuring the highest standards of quality assurance. IAG’s hand-assembled Short Blocks make it easy to upgrade your EJ25 Subaru engine, just leave the technical work to us, and we’ll provide you with a superior short block that’s ready to install.

What's Inside:

IAG Performance / Crest CNC Stage X 2.5L Billet Aluminum Short Block Includes:

- Case Halves - Crest Billet / Sleeved Case Halves

- Pinned Mains - Machine case for 9.5mm pinned mains and lined honed.

- Fire-Lock - IAG Fire-Lock™ receiver groove machining, latest solution to prevent head gasket failure on high horsepower and high boost Subaru's - *IAG Fire-Lock™ head gaskets required

- Machining - Machined for 14mm Head Studs *(Studs sold separately / Note the proper head gaskets or head gasket modifications are required for proper fitment with 14mm studs.

- Pistons - JE 99.5mm FSR 2618 custom forged pistons, JE Pro Seal Ring Set, .250" H13 .927" tool steel wrist pins, Clips

- Connecting Rods - Custom IAG-Spec +2mm Tri-Beam Forged Connecting Rods with ARP 625+ Rod Bolts.

- Rod / Main Bearings - ACL Race Bearings

- Crank - IAG-Spec Billet 79mm Crankshaft

- Case / Main Bolts - ARP Case Bolts

Compression Ratio:

- 8.5:1 on D Cylinder Heads (EJ255)

- 8.2:1 on B, V and W EJ257 Heads with standard thickness gasket.

Additional Options Available:

- Head Studs - IAG / ARP Spec 14mm head studs, nuts, and washers

- Oil Pumps - IAG Stage 2 CNC Ported 11mm EJ Oil Pump

- IAG Oil Pickup - Upgraded oil pickup featuring heavy gauge steel tubing, 2 point bracket & mesh filter

- IAG Oil Baffle - Upgraded oil control baffle and windage tray

- IAG Oil Pickup & Baffle Set - Upgraded oil pickup, oil control baffle, and windage tray

- Hardware / Seal Option - (Includes: Wrist pin plugs, washers, separator cover, bolts, etc. In case you don't want to transfer from the original engine).

Head Gasket Required:

- *IAG Fire-Lock .051" Head Gaskets with IAG-Spec Alloy Ring Set* PN# IAG-ENG-1741

Power Rating:

Power:The IAG / Crest CNC Stage X Short Block has a power output rating of 1150+BHP.

Hardware / Seal Option:

Not planning on reusing your original short block service plugs and covers? IAG offers a simple comprehensive cover and seal kit that includes (1) Rear main seal, (3) OEM wrist pin plugs, (3) OEM wrist pin plug washers, (1) OEM separator cover, (6) OEM separator cover bolts, (1) OEM wrist pin service cover, (1) OEM wrist pin service cover O-ring and (2) OEM wrist pin service cover screws. *If you are reusing your original wrist pin service plugs and covers, always replace the (3) OEM wrist pin plug washers and (1) wrist pin service cover O-ring before installing a short block to avoid potential leaks. *Never reuse a rear main seal on a new short block.

Head Gasket Option:

After years of research and development testing, the IAG Performance Fire-Lock™ head gasket is the newest solution to preventing head gasket failure on high horsepower and high boost Subaru EJ25 engines. This solution is loosely derived from diesel technology where a counterbore step is machined around each cylinder bore allowing specially sized fire rings to drop into the machined area and head gasket bores. The shims are designed to create a compression seal once the heads are installed and torqued into place. IAG fire rings are manufactured to a very strict tolerance from a proprietary alloy and are then put through a heat treatment process. The gaskets are manufactured from an asbestos-free composite raw material and feature a silicone based beading applied to critical areas to improve sealing around all water and oil passages. The combination of the alloy compression shims and gaskets assure maximum sealing for a Subaru EJ25 turbocharged engine.

*The IAG Fire-Lock™ gaskets require machine work for installation and are recommended for use with 14mm head stud hardware.

*The gaskets are sold in pairs with four Fire-Lock™ rings.

Features:

- Composite Material

- IAG-Spec Alloy Ring

- Specifically designed for 14mm Head Studs

- Silicone Beading

- 100mm Bore

- .051" Thickness

- Intended for High Horsepower, High Boost applications

- IAG ARP 14mm Head Studs Required

- Gaskets sold in pairs

Install Notes:

1. If a block or cylinder head was previously o-ringed the groove must be filled and resurfaced before using this type of gasket.

2. These gaskets require IAG ARP 14mm head studs to achieve the required torque necessary for proper installation.

3. Due to the required torque, any block that was previously honed will need to go to the next size overbore.

4. Future servicing will require cylinder head resurfacing due to an imprint left from the Fire-Lock™ rings.

Oil Pickup / Oil Baffle / Windage Tray Options:

The IAG Performance Subaru WRX / STI oil pickup was designed by Tigwerks to replace the OEM EJ25 oil pickup, which is prone to failure. It's a well-known fact that the OEM oil pickups often crack and fail which, in most cases, destroys your engine from lack of oil pressure. To avoid the cracking failures seen in the OEM oil pickup tubes, the Tigwerks oil pickup is manufactured from heavy-gauge steel tubing that is 3x thicker than OEM. Additionally, it features a flange machined from 3/8"Â 1018 CR steel to mate with the block, sealed with a Viton O-ring. The integrated heavy-duty mounting bracket uses two mounting points rather than the OEM single mounting point. Furthermore, the oil pickup features a formed bottom with an OEM style mesh screen for proper filtration. The TIG-welded oil pickup's increased material thickness, matched with the two-point heavy-duty mounting bracket, helps ensure that it does not fatigue and fail over time like an OEM unit.

The IAG Oil Control Baffle and Windage Tray System is designed to limit potential blow-by and prevent oil starvation in your Subaru's WRX / STI EJ engine during high rpm and high g-force driving. Through the use of Viton one-way flapper valves on our baffle and louvers in our windage tray, oil is prevented from reentering the upper crankcase area and is directed down into the oil pan to ensure plentiful supply to the oil pickup. IAG's integrated two-piece Oil Control Baffle and Windage Tray System is designed to work with our own oil pickup, as well as other oil pickups*. The baffle fits neatly in the engine crankcase area, allowing normal installation of the OEM oil pan and popular aftermarket pans*.

Oil Pickup & Baffle Install Notes

- EJ20 Subaru WRX engines require EJ25 oil pans for fitment

- IAG oil pickup spacer (Part# IAG-ENG-2081SP) is required when using IAG oil pickup with Killer B Oil Pan.

- *Does not work with Moroso oil pans or pickups

Oil Pump Option:

The 11mm Subaru Oil pump is one of the most popular off the shelf pumps to use on EJ25 engines. Originally equipped on the 2008-21 STI Dual AVCS engines, it provides an adequate amount of pressure and flow that fits the needs of many OE and built engines. But, as with almost anything, there is room for improvement.

Increasing oil flow volume and pressure in an EJ25 ensures that the bearings have sufficient oil film under all power levels and driving conditions. Additional oil flow to the engine provides a greater oil reserve to operate the AVCS solenoids and cam gears - giving you more consistent performance results.

The IAG Stage 2 CNC Ported 11mm oil pump was developed over years of servicing street and racing engines. In that time IAG has tested and utilized the majority of the popular Subaru oil pumps available on the market (JDM, Cosworth, ACL etc.) for customer, personal and racing vehicles.

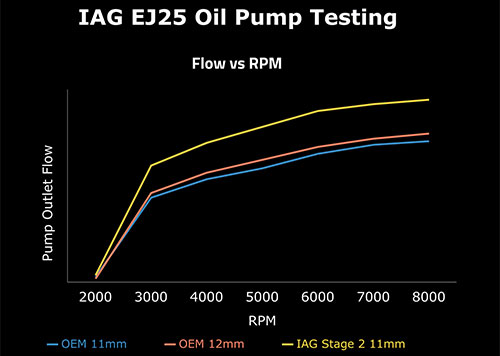

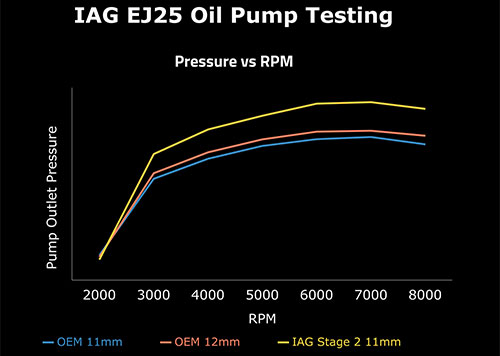

Over the last few years if you wanted an upgraded oil pump over the stock 11mm you would either buy a hand ported model from a trusted source, or often an OEM JDM (Japanese Market) 12mm pump. We believe that we have developed a better alternative. The IAG Stage 2 CNC Ported 11mm oil pumps have shown through lab testing on a Spintron Machine that it will outperform a JDM 12mm.

- Stage 2 flows 11.1% more oil than the OEM 11mm Oil Pump

- Stage 2 flows 9% more oil than the OEM 12mm Oil Pump

- Stage 2 oil pressure is 12.4% higher than the OEM 11mm Oil Pump

- Stage 2 oil pressure is 9.8% higher than the OEM 12mm Oil Pump

The Stage 2 Oil pump is a cost effective solution that outperforms the market standards. This pump has been extensively tested on street cars, track cars, and on our in-house Spintron to ensure consistent and repeatable performance.

Each IAG Stage 2 oil pump starts life as an OEM spec 11mm oil pump, straight from Subaru. IAG completely disassembles the new oil pump including pulling the rotors, backing plate & pressure relief valve. Next, the main body is fixtured in our in-house 5-Axis Centroid CNC machine where the inlet and outlet passageways are CNC ported. This allows for a larger, more consistent pathway for the oil into and out of the gerotor internals and helps to prevent cavitation. The Oil Pump Outlet where it meets the engine block is also CNC “Port Matched”, for a perfect transition into the engine block. The Inlet and Outlet sides of the gerotor are also opened up on the CNC mill to reduce inlet side cavitation, and to reduce outlet side pressure drops.

The pressure relief valve piston is REM Polished, which provides a non-directional, low Ra, polished finish. This reduces friction, heat and possibility of the relief valve piston galling and sticking, a common failure point on the OEM pumps.

The piston is reinstalled and confirmed to operate correctly. The rotors are measured and checked to be within the manufacturer's specification - aka Blueprinted, and installed next. The pump is then put together with a light coating of assembly lube to reduce friction and scuffing and aid in priming on first start up.

Finally, the backing plate is installed. Loctite is added to the hardware, and each piece receives a painted mark after it is correctly torqued. The pump ships ready to install, with all hardware and seals required for installation.

Installation Instructions:

Please review the PDF document below regarding installation, break-in procedures and warranty information.

PDF Closed Deck Install Guide for 1/2" & 14mm Head Studs

PDF After Sale Document - Contains Shipping, Engine Care and Warranty Information

Need Help Choosing a Block?

Our Experts Are Here to Help

We made this video to highlight the differences between each of our short blocks and to help you choose the best one for your performance goals and budget. Our Build Advisors and Customer Support staff can also assist you with any questions or concerns. Just click the button below for assistance.

Quality Guaranteed

Available 24 Month/24,000 Mile Warranty*

We stand behind every hand-built engine we produce. IAG's Standard Short Block Workmanship Warranty covers your short block for 12 months or 12,000 miles. We have also teamed up with a selection of IAG Certified Installation Facilities which offer up to a 24 month/24,000 mile workmanship warranty when the engine is purchased, installed, and tuned by that IAG Certified Installer.